2026 Top Trends in Pallet Transport: Innovations and Best Practices

Pallet Transport is evolving rapidly. As companies seek efficiency, new innovations emerge. These trends shape how goods move globally.

Technology is transforming pallet transport. Automation simplifies processes and reduces labor costs. Robotics streamline handling and improve accuracy. Eco-friendly pallets gain popularity, reflecting sustainability concerns.

However, challenges remain. Implementing new systems can be costly. Workers need training to adapt to these innovations. Balancing efficiency and safety is crucial. The future of pallet transport is bright, yet complex.

Emerging Technologies Impacting Pallet Transport in 2026

The pallet transport industry is evolving rapidly, driven by emerging technologies. In 2026, automation will play a crucial role. Many warehouses will adopt automated guided vehicles (AGVs). These machines can transport pallets smoothly, reducing the need for manual labor. However, the transition to automation may not be flawless. Workers may face challenges as they adapt to new systems. Training will be essential yet time-sensitive.

Data analytics will also transform pallet transport. Real-time tracking will allow companies to monitor shipments closely. This could improve efficiency significantly. Yet, relying on technology raises concerns about data privacy and cybersecurity. Companies must ensure robust measures are in place.

Sustainability remains a hot topic. More organizations are shifting towards eco-friendly materials for pallets. Innovations like biodegradable pallets are on the rise. While this shift is promising, the cost implications are still unclear for many businesses. The balance between innovation and budget remains a challenge. Embracing these technologies requires careful consideration and an openness to change.

2026 Top Trends in Pallet Transport: Innovations and Best Practices

| Trend | Description | Impact on Transport | Year of Adoption |

|---|---|---|---|

| Automation | Enhanced automation systems for loading, unloading, and sorting pallets. | Increased efficiency and reduced labor costs. | 2025 |

| IoT Integration | Real-time monitoring and tracking of pallets using IoT devices. | Improved visibility and inventory management. | 2026 |

| Sustainable Materials | Using biodegradable and recyclable materials for pallets. | Reduction of environmental footprint in transport. | 2026 |

| Smart Pallet Systems | Pallets equipped with smart sensors for tracking and performance analysis. | Enhanced operational insights and decision making. | 2025 |

| Data Analytics | Utilizing big data to optimize pallet transport routes and load planning. | Cost savings and improved delivery times. | 2026 |

Sustainable Practices in Pallet Transport: Eco-friendly Innovations

The pallet transport industry is increasingly leaning towards sustainable practices. Innovations are emerging that focus on reducing waste and enhancing efficiency. For instance, biodegradable pallets are gaining traction. These pallets offer a greener alternative that can break down naturally, minimizing landfill impact.

Another promising development is the use of recycled materials in pallet manufacturing. Companies are exploring how to create durable pallets from scrap materials. This not only reduces the need for new resources but also encourages a circular economy approach. However, the challenge remains in ensuring these recycled pallets meet industry standards for strength and safety.

While many companies strive for eco-friendly practices, implementation is not always seamless. Some find it difficult to balance cost with sustainability. They may feel constrained by budgets or supply chain limitations. Reflecting on these hurdles is essential as the industry seeks to innovate responsibly. The road toward sustainable pallet transport is complex, requiring constant adjustments and reflections on what works and what doesn't.

Automation and Robotics: The Future of Pallet Handling

Automation and robotics are revolutionizing pallet handling in transport. These technologies enhance speed and efficiency. Automated systems reduce human error and increase safety. As warehouses grow, the demand for faster operations rises. Robots can navigate tight spaces and handle heavy loads. However, challenges still exist.

Tips: Start with small automation projects. Assess your current workflow first. Incremental changes can lead to smoother transitions. Ensure proper training for staff when integrating new systems.

Implementing robotics does require investment. Not every operation can afford it right away. Some companies report mixed results during initial trials. Proper planning is crucial. Focus on long-term benefits while addressing short-term hiccups. Monitoring performance will help identify areas needing adjustment.

Tips: Analyze data regularly. Adapt systems based on performance insights. Stay flexible and be open to change. Embrace uncertainties while exploring automation's potential.

Data Analytics in Supply Chain: Enhancing Pallet Transport Efficiency

Data analytics is revolutionizing pallet transport efficiency. By leveraging large data sets, companies can optimize their supply chain processes. This approach allows firms to track pallet movements in real time. Visibility leads to better decision-making. With accurate insights, managers can predict demand shifts. This minimizes delays and reduces costs.

However, the adoption of data analytics presents challenges. Some organizations struggle to integrate new technologies. There is a learning curve for staff. Without proper training, data analysis can remain underutilized. Moreover, reliance on data can sometimes lead to overlooking human factors. Employees on the ground often have valuable insights that numbers cannot capture.

Balancing data and human input is key. Regular feedback loops can improve systems. Companies must be open to adjusting their strategies. Experimentation might not always yield perfect results. Yet, these reflections can guide more effective pallet transport methods. The synergy between data and experience can drive long-term improvements.

2026 Top Trends in Pallet Transport

This chart illustrates the percentage impact of various innovations and best practices on pallet transport efficiency. Data analytics and real-time tracking stand out as the most significant influences, showcasing the importance of technology in optimizing supply chain processes.

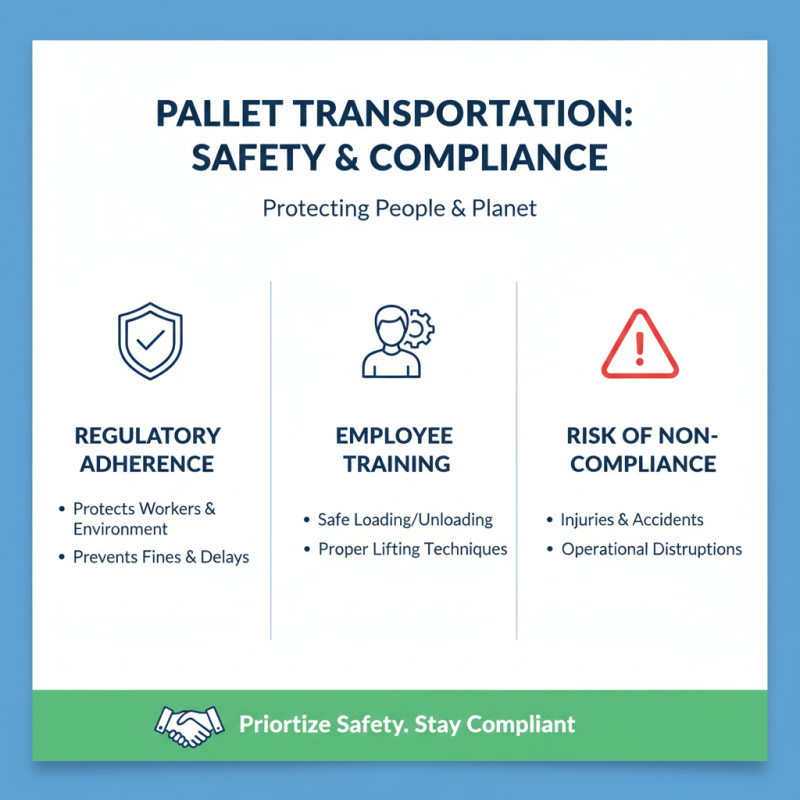

Best Practices for Safety and Compliance in Pallet Transportation

In pallet transportation, safety and compliance are critical. Adhering to regulations protects workers and the environment. Regular training ensures employees understand safe loading and unloading procedures. It is vital to instruct team members on proper lifting techniques. Neglecting these practices can lead to injuries.

Consider the conditions during transport. Fluctuating temperatures can affect cargo integrity. Use temperature monitoring systems for sensitive materials. Inspections before dispatch are often overlooked. However, they can prevent significant losses and liabilities. Regular vehicle maintenance is also essential to avoid mechanical failures.

Communication plays a key role in compliance. Clear signages in warehouses and transport routes help prevent accidents. Regular safety drills create awareness and readiness. It’s important to reflect on potential lapses in procedures. Consistency is the key to maintaining a culture of safety. Over time, monitoring practices will reveal areas needing improvement.

Related Posts

-

What is Pallet Transport? Understanding Its Importance and Benefits in Logistics

-

2025 Top Trends in European Rail Transport You Need to Know

-

2025 How to Optimize Container Transport for Global Shipping Efficiency

-

Top 10 Benefits of Multi Echelon Inventory Optimization for Supply Chain Management

-

Understanding Tk Logistics And Warehousing Services For Your Business Needs

-

Top 5 Benefits of Multi Echelon Inventory Optimization: Boost Efficiency by 30%