Top 10 Benefits of Multi Echelon Inventory Optimization for Supply Chain Management

In today's fast-paced and complex supply chain landscape, effective inventory management has become a critical factor for success. Multi Echelon Inventory Optimization (MEIO) has emerged as a transformative approach that enables businesses to streamline their inventory management processes across various levels of their supply chain. By looking at inventory holistically—from suppliers to warehouses and onto retail locations—companies can significantly improve their efficiency and responsiveness to demand fluctuations. This paradigm shift not only enhances operational performance but also leads to substantial cost savings and improved service levels.

The benefits of adopting Multi Echelon Inventory strategies are profound, touching upon aspects such as improved forecasting, reduced stockouts, and optimized safety stock levels. These advantages allow organizations to better align their inventory with actual demand, resulting in minimized excess inventory and waste. As businesses continue to face challenges like rising customer expectations and global supply chain disruptions, the implementation of MEIO can serve as a vital tool for enhancing resilience and agility. In this article, we will explore the top ten benefits of Multi Echelon Inventory Optimization in supply chain management and how it can drive significant improvements in overall performance and customer satisfaction.

Understanding Multi Echelon Inventory Optimization Concepts

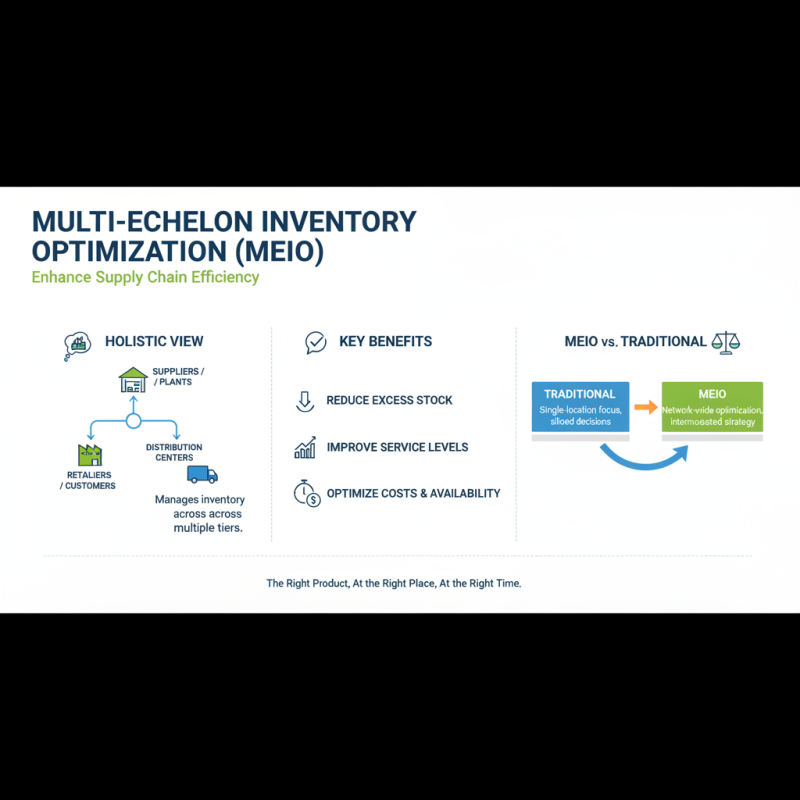

Multi Echelon Inventory Optimization (MEIO) is a sophisticated approach designed to enhance supply chain efficiency by managing inventory across multiple levels of the supply chain. Unlike traditional inventory management, which often focuses on single locations or levels, MEIO takes into account complex interactions between different tiers of inventory. This holistic view allows businesses to optimize stock levels, reduce excess inventory, and improve service levels by ensuring that the right products are available at the right locations and times.

One of the core concepts of MEIO is the balancing act between supply and demand across the entire supply chain network. By analyzing demand variability and lead times, organizations can develop more accurate inventory strategies that align with customer needs while minimizing costs. Additionally, MEIO uses advanced algorithms and predictive analytics to simulate various scenarios, providing insights that help businesses make informed decisions about inventory placement and replenishment. This proactive management approach not only increases overall efficiency but also enhances responsiveness to market changes, ultimately driving greater customer satisfaction.

Key Benefits of Enhanced Inventory Accuracy Across Supply Chains

Enhanced inventory accuracy is a crucial component of multi-echelon inventory optimization in supply chain management. According to a report by Gartner, organizations with high inventory accuracy can reduce excess stock by up to 30%, significantly improving cash flow and freeing up resources for other business needs. Accurate inventory information enables companies to forecast demand more effectively, leading to better service levels and lower stockouts. In fact, companies that have implemented robust inventory management systems have reported a 10-20% increase in order fulfillment rates, enhancing overall customer satisfaction.

Moreover, inventory accuracy plays a pivotal role in minimizing costs associated with inefficiencies. The 2022 State of Supply Chain Optimization report highlights that firms achieving optimization in inventory management can lower their operational costs by 15-25%. This is achieved through reduced holding costs, improved warehouse management, and streamlined logistics. Enhanced accuracy allows for more precise ordering and replenishment processes, reducing the likelihood of obsolete stock, and subsequently, the costs associated with disposal or markdowns. In today's competitive environment, leveraging accurate inventory data is not just a best practice—it’s a necessity for sustaining profitability and maintaining a competitive edge.

Improving Customer Satisfaction through Inventory Optimization

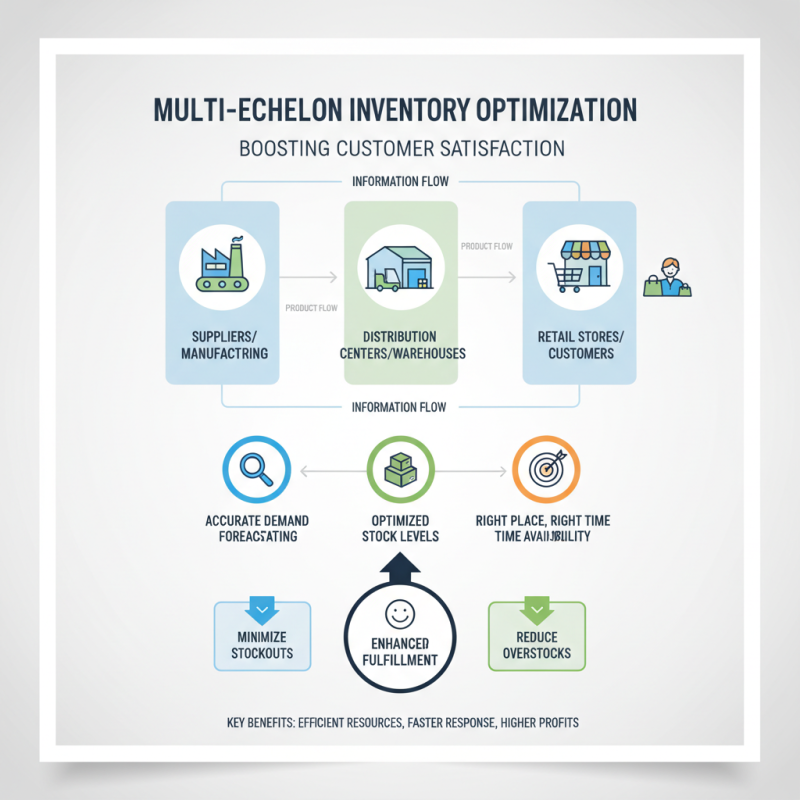

In today's competitive market, optimizing inventory across multiple echelons is crucial for enhancing customer satisfaction. Effective multi-echelon inventory optimization allocates resources efficiently and ensures that products are available at the right place and time. This proactive approach minimizes stockouts and overstock situations, which directly impacts customer experience. By accurately forecasting demand and streamlining inventory levels, businesses can respond swiftly to consumer needs, ultimately leading to higher levels of customer fulfillment.

Moreover, improving inventory management creates a seamless supply chain that enhances reliability. Customers expect timely deliveries and product availability; therefore, a well-optimized inventory system can reduce lead times and improve service levels. When companies maintain optimal inventory across various locations, they not only mitigate risks but also build trust with their customers. This trust cultivates loyalty, as customers are more likely to return when they have consistently positive experiences. Therefore, investing in multi-echelon inventory optimization is essential for businesses aiming to boost customer satisfaction and foster long-term relationships.

Cost Reduction Strategies Enabled by Multi Echelon Approaches

Multi-echelon inventory optimization (MEIO) is a systematic approach that enhances supply chain efficiency by managing inventories across multiple levels—from suppliers to warehouses to retail outlets. One of the primary benefits of adopting MEIO is its capacity for significant cost reduction. By analyzing demand patterns and inventory levels at each echelon, businesses can minimize excess stock and reduce carrying costs. This not only leads to improved cash flow but also ensures that funds are allocated more effectively across the supply chain.

Implementing multi-echelon strategies enables organizations to refine their stock replenishment processes. By employing advanced forecasting techniques, businesses can better anticipate demand fluctuations and avoid stockouts or overstock situations. This dynamic approach to inventory management means that resources are utilized more efficiently, resulting in lower operational expenses.

Tips: To implement effective multi-echelon inventory optimization, focus on enhancing data accuracy and leveraging real-time analytics. Regularly review your inventory metrics to identify areas for improvement and ensure that all tiers of your supply chain are aligned in terms of goals and strategies. Engaging in ongoing training for your team will further maximize the effectiveness of your MEIO efforts, creating a more responsive and cost-efficient supply chain.

Top 10 Benefits of Multi Echelon Inventory Optimization for Supply Chain Management

This bar chart illustrates the key benefits of implementing multi echelon inventory optimization in supply chain management. The benefits include cost reduction, improved service levels, better inventory turnover, and enhanced demand forecasting, among others.

Impact of Inventory Optimization on Supply Chain Agility and Flexibility

Multi echelon inventory optimization (MEIO) plays a crucial role in enhancing supply chain agility and flexibility, which are vital components for businesses operating in today's fast-paced market. By effectively managing inventory across multiple levels of the supply chain—from suppliers to distribution centers to retail outlets—companies can significantly reduce lead times and improve responsiveness to customer demand. According to a report by the Institute for Supply Management, organizations that implement MEIO can reduce inventory levels by up to 30% while maintaining desired service levels, thereby creating a more agile operational framework.

The impact of inventory optimization also extends to improving flexibility within the supply chain. With a multi-echelon approach, companies gain better visibility and control over their inventory, enabling them to quickly adapt to changing market conditions and consumer preferences. Research from the Council of Supply Chain Management Professionals indicates that companies that embrace such optimization strategies can achieve up to a 20% increase in their fill rate, ultimately leading to enhanced customer satisfaction and loyalty. By fostering a responsive supply chain environment, businesses can not only survive but thrive in the volatile marketplace, ensuring they are equipped to meet both current and future challenges effectively.

Top 10 Benefits of Multi Echelon Inventory Optimization for Supply Chain Management - Impact of Inventory Optimization on Supply Chain Agility and Flexibility

| Benefit | Description | Impact on Agility | Impact on Flexibility |

|---|---|---|---|

| Improved Forecasting | Enhances accuracy in inventory needs, reducing excess stock. | High | Medium |

| Reduced Lead Times | Optimizes order processing and delivery routes. | High | Medium |

| Cost Reduction | Minimizes holding costs and stockouts. | Medium | Medium |

| Enhanced Visibility | Provides real-time updates across the supply chain. | High | High |

| Better Supplier Collaboration | Facilitates communication and logistics planning. | Medium | High |

| Scalability | Easily adapts to changing demand and market conditions. | High | High |

| Improved Customer Service | Fulfills customer orders promptly, enhancing satisfaction. | High | Medium |

| Data-Driven Insights | Utilizes analytics for informed decision-making. | Medium | Medium |

| Reduced Stockouts | Minimizes the chances of running out of key products. | High | Medium |

| Sustainability | Optimizes resource use, contributing to environmental goals. | Medium | High |

Related Posts

-

Top 5 Benefits of Multi Echelon Inventory Optimization: Boost Efficiency by 30%

-

Understanding Multi Echelon Inventory: Key Benefits and Best Practices

-

10 Best Managed Inventory Tips for Streamlining Your Business Operations

-

2025 How to Optimize Container Transport for Global Shipping Efficiency

-

Top 10 Tips for Choosing Tk Logistics and Warehousing Solutions

-

Understanding Tk Logistics And Warehousing Services For Your Business Needs