10 Best Managed Inventory Tips for Streamlining Your Business Operations

Effective inventory management is crucial for any business looking to operate efficiently and maintain a competitive edge. In today's fast-paced market, having a well-organized system for tracking and managing inventory can greatly streamline operations, reduce costs, and improve customer satisfaction. One key approach to achieving these goals is through "Managed Inventory." This strategy not only helps businesses keep their stock levels optimized but also aligns procurement with demand, ensuring that resources are utilized effectively.

By implementing the best practices for managed inventory, companies can navigate the complexities of supply chain management more adeptly. These practices include utilizing technology for real-time tracking, employing demand forecasting, and maintaining strong supplier relationships. Each of these elements plays a significant role in ensuring that businesses can respond quickly to changes in market demand while minimizing excess stock and associated carrying costs. In this guide, we will explore the 10 best managed inventory tips that can transform how your business operates, paving the way for increased efficiency and profitability.

Understanding the Importance of Efficient Inventory Management

Efficient inventory management is crucial for any business seeking to optimize its operations and enhance profitability. By ensuring that the right products are available at the right time, businesses can significantly reduce storage costs, minimize waste, and improve customer satisfaction. An organized inventory system allows companies to respond swiftly to market demands, avoiding the pitfalls of overstocking or stockouts that can lead to lost sales and dissatisfied customers.

Moreover, understanding inventory levels through consistent monitoring and reporting can provide valuable insights into purchasing patterns and consumer behavior. This data-driven approach empowers businesses to make informed decisions regarding restocking and product diversification. Implementing techniques such as just-in-time inventory or utilizing automated inventory management software can further streamline operations, ultimately leading to a more agile and responsive business framework. Efficient inventory management not only enhances operational efficiency but also cultivates a competitive edge in the marketplace.

Analyzing Demand Forecasting Techniques for Inventory Control

Effective demand forecasting techniques are essential for optimizing inventory control and streamlining business operations. By accurately predicting customer needs, businesses can reduce excess stock, minimize shortages, and enhance overall efficiency. Utilizing historical sales data, market trends, and even seasonal fluctuations can help create a more reliable forecast. One valuable tip is to leverage technology, such as predictive analytics tools, which can analyze complex data sets for more precise forecasting.

Another important strategy is to incorporate feedback loops. Regularly reviewing inventory levels and sales trends allows for real-time adjustments to the forecasting model. This continuous improvement approach ensures that your inventory remains aligned with market demands. Additionally, consider segmenting your inventory based on product categories. By tailoring forecasting techniques to specific segments, you can fine-tune your approach and respond more agilely to changes in demand.

Finally, collaboration with suppliers can significantly enhance your forecasting accuracy. Share insights about market conditions and anticipated demand shifts, which can lead to better inventory planning. Strong communication with your supply chain partners facilitates better alignment and responsiveness, ultimately leading to more streamlined business operations. Implementing these demand forecasting techniques will undoubtedly support more effective inventory control and contribute to your business’s success.

Implementing Inventory Tracking Systems and Technology

Implementing inventory tracking systems and technology is essential for streamlining business operations and enhancing efficiency. One effective tip is to invest in a robust inventory management software that integrates seamlessly with your existing systems. This technology provides real-time data on stock levels, allowing businesses to make informed decisions and reduce excess inventory costs. By automating tedious tasks, companies can also minimize errors associated with manual tracking, saving both time and resources.

Another valuable strategy is to utilize barcode scanning or RFID technology to improve accuracy and speed in inventory tracking. These tools ensure that items are correctly logged and their movements are accurately tracked throughout the supply chain. Incorporating mobile devices into the inventory process allows employees to perform stock checks and update records instantly, further streamlining operations.

Finally, regularly reviewing and analyzing your inventory data can lead to better forecasting and stock management. By identifying trends and patterns in sales, businesses can optimize their inventory levels and avoid stockouts or overstock situations. Embracing these inventory tracking systems and technologies will lead to more efficient, cost-effective business operations.

Inventory Management Efficiency: Monthly Overview

This bar chart illustrates the inventory turnover ratio over the first seven months of the year, showcasing an increasing trend which indicates improved inventory management efficiency.

Strategies for Optimizing Reorder Points and Stock Levels

Effective inventory management is crucial for streamlining business operations, particularly when it comes to optimizing reorder points and stock levels. One of the best strategies is to implement a data-driven approach that uses real-time sales forecasts to predict inventory needs accurately. This helps ensure that stock levels are maintained efficiently, minimizing both overstock and stockouts.

Another important tip is to leverage technology, such as AI and automated systems, to enhance supply chain management. For instance, the introduction of AI in operations can significantly improve the logistics of parts supply, leading to better customer service and optimized inventory turnover. By establishing a responsive supply chain, businesses can adapt quickly to market changes, maintaining an agile operation that meets customer demands.

Lastly, regularly reviewing and adjusting reorder points is essential. Changes in sales velocity, seasonality, or market trends should prompt inventory reviews to refine these thresholds. This ongoing assessment ensures that inventory levels are aligned with actual demand, ultimately contributing to a more efficient and streamlined operation.

10 Best Managed Inventory Tips for Streamlining Your Business Operations

| Tip | Description | Benefit |

|---|---|---|

| 1. Set Reorder Points | Establish minimum stock levels to trigger orders. | Avoid stockouts and lost sales. |

| 2. Use Inventory Management Software | Implement software for tracking inventory in real time. | Enhance accuracy and reduce manual errors. |

| 3. Perform Regular Audits | Conduct periodic checks to assess stock levels. | Identify discrepancies and improve tracking. |

| 4. Implement FIFO/LIFO Methods | Choose an inventory valuation method that suits your business. | Optimize inventory flow and cost management. |

| 5. Analyze Sales Trends | Monitor sales data to adjust stock levels accordingly. | Align inventory with customer demand. |

| 6. Prioritize Inventory Levels | Classify items by importance and manage them accordingly. | Focus on high-impact inventory management. |

| 7. Negotiate with Suppliers | Work on better terms for lead times and minimum order quantities. | Reduce costs and improve cash flow. |

| 8. Utilize Just-in-Time Inventory | Order stock to arrive when needed to reduce holding costs. | Enhance efficiency and minimize waste. |

| 9. Enhance Communication | Maintain clear communication with suppliers and staff. | Improve order accuracy and operational efficiency. |

| 10. Train Staff Regularly | Provide ongoing training in inventory management best practices. | Ensure all staff are equipped to manage inventory effectively. |

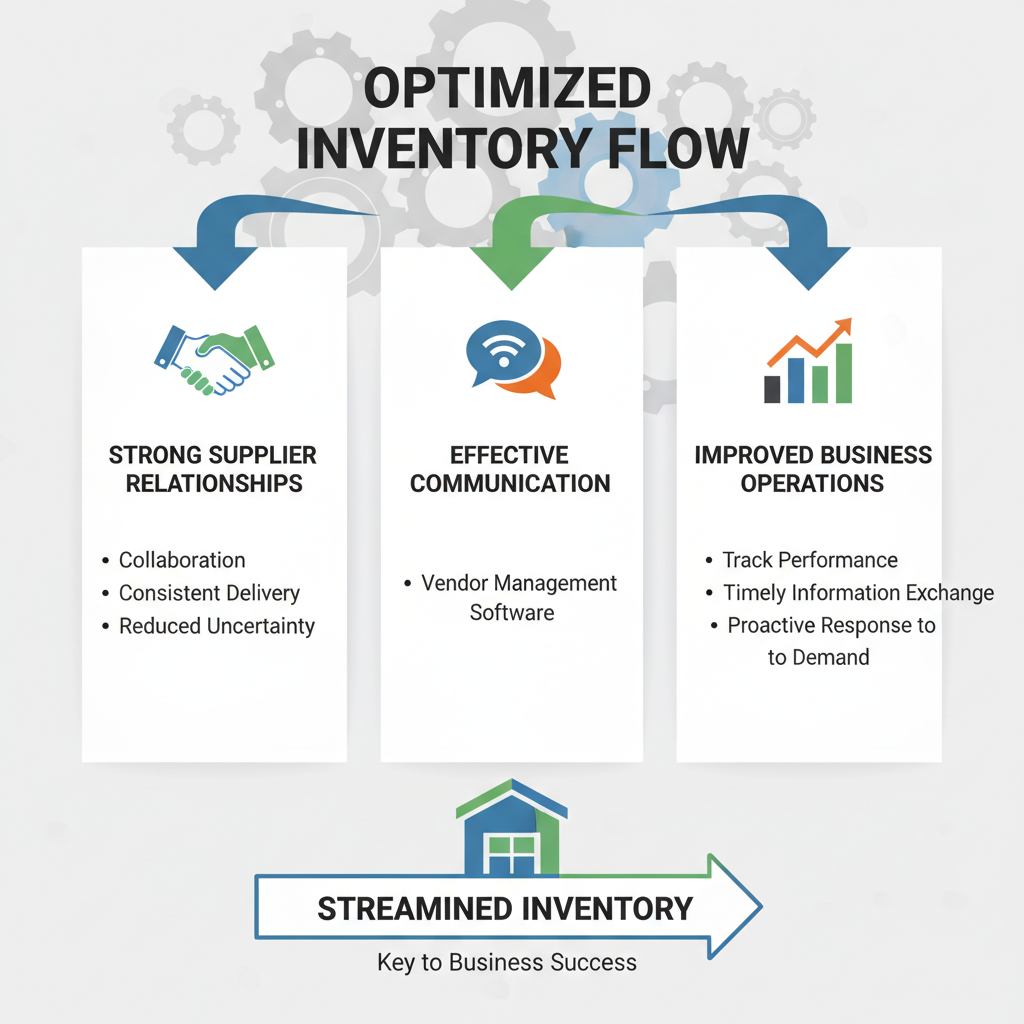

Integrating Supplier Relationships for Improved Inventory Flow

Integrating strong supplier relationships is essential for streamlining inventory flow and improving overall business operations. By fostering collaboration with suppliers, businesses can achieve more consistent delivery schedules, reducing uncertainty in inventory management. Effective communication is crucial; utilizing vendor management software can help track performance metrics and facilitate timely exchanges of information. This ensures that both parties are aligned on expectations and can respond proactively to changes in demand.

Another tip for managing inventory effectively is to embrace technology. The integration of artificial intelligence (AI) into supply chain management offers innovative solutions for real-time inventory tracking and predictive analytics. AI tools can help identify patterns in purchasing behaviors, allowing businesses to optimize their stock levels and reduce excess inventory. As AI evolves, businesses must stay informed about emerging startups and technologies that can further enhance their inventory strategies, from automated ordering systems to advanced forecasting models.

Related Posts

-

Top 5 Benefits of Multi Echelon Inventory Optimization: Boost Efficiency by 30%

-

2025 How to Optimize Intermodal Freight Train Efficiency and Reduce Costs

-

2025 How to Optimize Container Transport for Global Shipping Efficiency

-

How to Optimize Airfreight Logistics for Faster International Shipping

-

10 Essential Tips for Optimizing Tk Logistics and Warehousing Efficiency