Top Tips for Efficient Railway Freight Management?

Efficient railway freight management is essential in today’s logistics landscape. Businesses rely on it for timely deliveries. Railway freight systems enhance capacity and reduce costs compared to road transport. However, they are often underutilized due to mismanagement.

Understanding the complexities of railway freight is crucial. The schedules can be unpredictable, and infrastructure may not always support optimal operations. Adjustments may be needed to meet specific requirements. This can include improving communication among stakeholders and investing in technology for tracking.

Focusing on effective strategies can yield significant benefits. Companies need to explore options for enhancing reliability. They should consider training staff to better manage resources. By addressing potential inefficiencies, businesses can unlock the full potential of railway freight services. The path might be challenging, but the rewards justify the effort.

Understanding the Basics of Railway Freight Management

Railway freight management is crucial for the efficient movement of goods. Understanding its basics can drastically improve logistics operations. In 2021, rail transport accounted for about 28% of freight volume in Europe, showcasing its importance. Efficient management can lead to cost savings and fewer delays.

Tip 1: Focus on route optimization. Analyze current routes and identify bottlenecks. Reports show that optimized routes can reduce transit times by up to 15%. Adjustments can lead to significant improvements.

Moreover, communication is key in railway freight management. In a survey, 60% of companies reported that clear communication with all stakeholders improved their overall efficiency. Lack of transparency can lead to costly mistakes. Timely updates on shipment status are essential.

Tip 2: Invest in technology for tracking. Real-time tracking can enhance visibility. Data from the logistics sector indicates that implementing tracking solutions can reduce loss rates by nearly 20%. However, ensuring complete accuracy remains a challenge for many operators.

In conclusion, understanding the foundations of railway freight management, including optimization and technology, can transform logistics processes. Yet, it's vital to continuously assess and improve strategies for better outcomes.

Top Tips for Efficient Railway Freight Management

This chart represents the average delivery times (in days) for different types of railway freight management solutions, illustrating the efficiency of various strategies.

Key Factors Influencing Railway Freight Efficiency

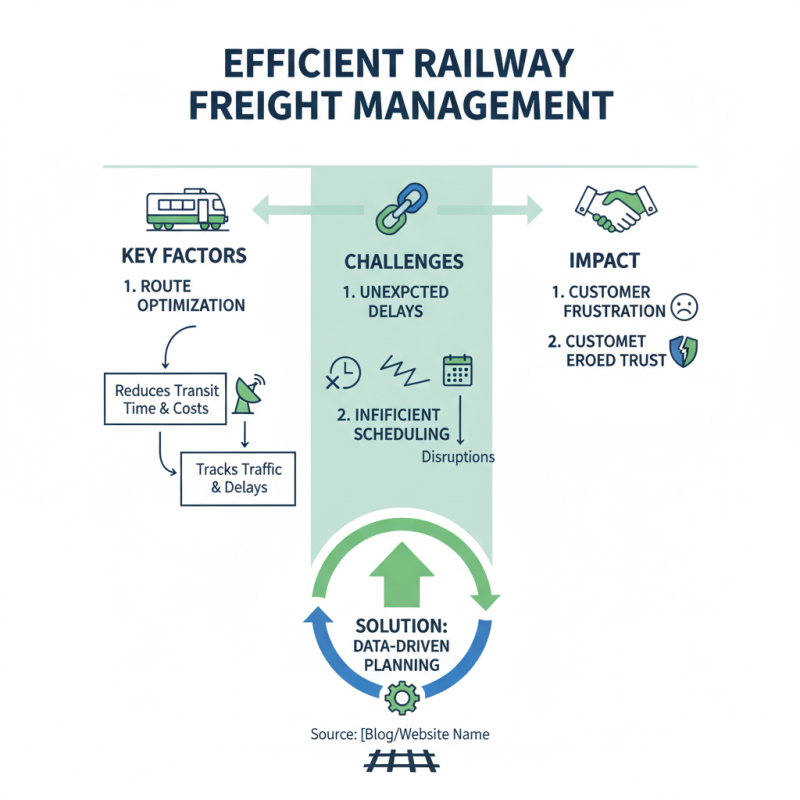

Efficient railway freight management depends on various key factors that can significantly impact operations. The choice of routing plays a crucial role. Utilizing the most efficient route reduces transit times and costs. However, planning these routes requires continuous monitoring of traffic patterns. Trains may encounter unexpected delays, leading to inefficient scheduling. Such disruptions can frustrate customers and affect overall trust.

Another essential factor is proper maintenance of rolling stock. Regular inspections prevent breakdowns during crucial transport periods. Yet, the reality is that not all rail operators invest adequately in maintenance. Over time, this neglect can lead to significant operational issues, including delays and cancellations. Timely upkeep should never be overlooked.

Communication between all stakeholders is vital. Clear lines of dialogue among shippers, railway operators, and customers enhance coordination. However, miscommunication is often common. It can lead to errors in shipment details, causing unnecessary delays. Building robust communication protocols helps mitigate these risks, but challenges remain. Each of these factors requires ongoing assessment and reflection for continuous improvement in freight efficiency.

Strategies for Optimizing Loading and Unloading Processes

Efficient loading and unloading processes are crucial in railway freight management. According to industry studies, up to 38% of freight delays stem from inefficient loading practices. To address this, rail companies can implement standardized loading procedures. This reduces confusion and minimizes time spent during the transition.

Utilizing technology can also enhance efficiency. Real-time tracking systems help monitor cargo movement. A report from the Transportation Research Board indicates that companies employing such technology see a 15% decrease in unloading time. Moreover, training staff on these systems is vital. Even small lapses in training can lead to increased delays.

Accountability is essential in this process. Each member of the team should understand their role in loading and unloading. Poor communication can create bottlenecks. A study from FreightWaves found that 70% of participants cited lack of communication as a significant obstacle during loading. Reflecting on these points can lead to improved practices and reduce costs significantly.

Utilizing Technology for Enhanced Freight Tracking and Reporting

Efficient railway freight management relies heavily on technology. Enhanced tracking systems can transform logistics. Real-time data provides visibility into cargo locations. It's crucial for timely deliveries and efficient operations.

Investing in digital platforms can streamline reporting. Automated systems collect and analyze data much faster than manual methods. However, implementation can be challenging. Training staff and integrating new technologies might slow initial progress. Yet, the long-term benefits are undeniable.

Moreover, using mobile applications allows for instant updates. Stakeholders can track shipments remotely. This creates transparency and improves communication between teams. But not all users adopt new technologies quickly. Some may need extra support and time to adjust. Addressing these issues is key to a successful transition.

Best Practices for Collaborating with Railway Service Providers

Collaborating with railway service providers can enhance freight management efficiency. Start by establishing clear communication channels. Regular updates on schedules and availability help avoid delays. Meetings can clarify expectations and ensure everyone is aligned.

Building strong relationships with railway partners is vital. Trust fosters a proactive environment. Both parties should share insights on capacity fluctuations. Understanding each other's challenges can lead to better solutions. It is essential, however, to remain realistic about capabilities. Not every request will be met promptly.

Documenting processes is another essential practice. Accurate records of shipments prevent misunderstandings. Yet, documentation can sometimes be overlooked. Many companies struggle with this aspect. Investing time in accurate tracking can pay off significantly. Continuous feedback loops are also important. Review what worked and what didn’t, and adjust plans accordingly.

Top Tips for Efficient Railway Freight Management

| Tip | Description | Best Practice | Expected Outcome |

|---|---|---|---|

| Plan Routes Effectively | Analyze the best routes for transporting goods to minimize delays. | Use route optimization software. | Reduced transportation time and costs. |

| Enhance Communication | Maintain clear communication channels with railway service providers. | Set regular update meetings. | Improved coordination and fewer misunderstandings. |

| Utilize Technology | Implement tracking and management systems for freight. | Adopt RFID or GPS tracking. | Real-time visibility of cargo status. |

| Focus on Safety | Ensure compliance with safety regulations and protocols. | Regular safety training for staff. | Lower risk of accidents and loss. |

| Regularly Review Performance | Conduct periodic assessments of service and performance metrics. | Use KPIs to evaluate efficiency. | Continuous improvement of processes. |

Related Posts

-

What is International Cargo and How Does It Impact Global Trade

-

What is Pallet Transport? Understanding Its Importance and Benefits in Logistics

-

2026 Top Trends in Pallet Transport: Innovations and Best Practices

-

2025 Top Trends in European Rail Transport You Need to Know

-

Understanding Multi Echelon Inventory: Key Benefits and Best Practices

-

How to Optimize Groupage Transport for Cost Effective Shipping Solutions