Understanding Multi Echelon Inventory: Key Benefits and Best Practices

In today's rapidly evolving supply chain landscape, the concept of Multi Echelon Inventory (MEI) stands out as a strategic approach that enhances inventory management across various levels of distribution. According to Dr. Michael Watson, a leading expert in supply chain optimization, "Multi Echelon Inventory is not just about storing products at multiple locations; it's about strategically positioning inventory to ensure optimal service levels while minimizing costs." This holistic view of inventory management enables organizations to balance demand and supply more efficiently, reducing the risk of stockouts and excess inventory.

As businesses increasingly face the challenges of fluctuating demand and complex supply networks, embracing Multi Echelon Inventory has become crucial. By understanding and implementing MEI practices, companies can better align their inventory strategies with customer needs, ultimately driving profitability and customer satisfaction. The key benefits of this approach include improved inventory turnover, enhanced visibility across the supply chain, and a more agile response to market changes.

In this article, we will delve into the core benefits of Multi Echelon Inventory, along with best practices that organizations can adopt to leverage this powerful strategy effectively. By focusing on multi-echelon solutions, businesses can transform their inventory management processes and gain a competitive advantage in the marketplace.

Understanding Multi Echelon Inventory: Definition and Key Concepts

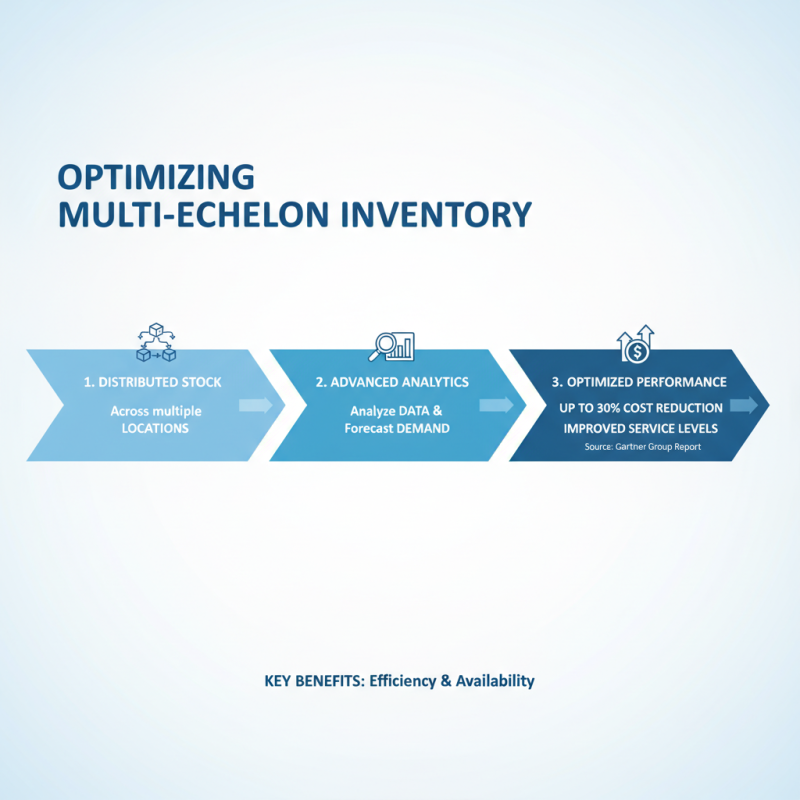

Multi-echelon inventory (MEI) is a strategic approach that involves managing inventory across multiple levels of a supply chain, from suppliers to warehouses to retail locations. This system aims to optimize inventory levels while balancing the service level and costs. According to a report from the Council of Supply Chain Management Professionals, companies that implement MEI strategies can reduce overall inventory costs by up to 30% while maintaining, or even improving, service levels. This approach allows businesses to respond more agilely to demand fluctuations, thereby reducing stockouts and excess inventory.

Understanding the key concepts of MEI is essential for businesses looking to enhance their operational efficiency. Concepts such as inventory positioning, which determines where to hold stocks within the network, and inventory visibility, which ensures real-time tracking of stock levels, play crucial roles in effective MEI. Research by Gartner indicates that organizations with enhanced inventory visibility experience a 20% improvement in their inventory turnover ratios. By leveraging data analytics and advanced forecasting methods, companies can create a more responsive supply chain that accurately reflects customer demand, resulting in significant cost savings and improved customer satisfaction.

Understanding Multi Echelon Inventory: Key Benefits and Best Practices

| Dimension | Description | Benefit |

|---|---|---|

| Inventory Levels | The quantity of stock held at each echelon in the supply chain. | Optimized levels reduce carrying costs. |

| Demand Forecasting | Predicting customer demand to better align inventory. | Improved service levels and reduced stockouts. |

| Lead Time Management | Time taken from ordering to receiving inventory. | Enhanced responsiveness to market changes. |

| Safety Stock | Buffer inventory held to prevent stockouts. | Increased service reliability and customer satisfaction. |

| Inventory Visibility | Ability to track inventory across different locations. | Better decision-making and reduced inefficiencies. |

Importance of Multi Echelon Inventory in Supply Chain Efficiency

Multi-echelon inventory systems play a crucial role in enhancing supply chain efficiency by ensuring that the right products are available at the right time and place. This system enables businesses to manage inventory across multiple storage locations—such as warehouses and distribution centers—allowing them to optimize stock levels and minimize excess inventory. By coordinating inventory levels across different echelons, organizations can respond to fluctuations in demand more effectively, reducing the risk of stockouts or overstock situations that can disrupt operations.

The importance of multi-echelon inventory also extends to improved forecasting and planning. By analyzing inventory data at various levels within the supply chain, organizations can gain valuable insights into demand patterns and customer behavior. This leads to more accurate inventory replenishment strategies, which can decrease holding costs and enhance overall service levels. Furthermore, implementing best practices in multi-echelon inventory management can foster collaboration among supply chain partners, leading to shared responsibilities and improved visibility throughout the supply chain. Ultimately, an effective multi-echelon inventory strategy not only boosts operational efficiency but also strengthens the competitive position of businesses in the marketplace.

Key Benefits of Implementing Multi Echelon Inventory Strategies

Implementing multi-echelon inventory strategies can bring significant advantages to organizations seeking to optimize their supply chains. One of the key benefits is improved inventory turnover rates. By effectively managing and positioning inventory across various levels in the supply chain, businesses can ensure that products are available where and when they are needed, reducing excess stock and minimizing holding costs. This results in a more agile supply chain that can respond swiftly to changes in demand.

Effective demand forecasting is another crucial benefit of multi-echelon inventory systems. With a better understanding of inventory requirements at different echelons, organizations can predict customer demand more accurately. This enables them to adjust inventory levels accordingly, ensuring that they have just enough stock on hand to meet customer needs without overstocking.

**Tips:** To maximize the benefits of multi-echelon inventory, companies should focus on enhancing collaboration across departments, integrating real-time data analytics, and investing in technology that supports inventory visibility. Additionally, conducting regular reviews of inventory metrics can help identify areas for improvement and ensure that the inventory strategy remains aligned with overall business objectives. By implementing these best practices, organizations can unlock greater efficiency and drive profitability in their supply chains.

Understanding Multi Echelon Inventory: Key Benefits of Implementing Strategies

Best Practices for Managing Multi Echelon Inventory Effectively

Managing multi echelon inventory effectively is essential for optimizing supply chain performance and ensuring product availability. A multi echelon inventory system distributes stock across various locations, enabling businesses to better respond to customer demand fluctuations. One best practice in managing such systems is to implement advanced analytics tools that can analyze historical data and forecast future demand accurately. According to a report by the Gartner Group, companies utilizing predictive analytics for inventory management can reduce their overall inventory holding costs by as much as 30%, while simultaneously improving service levels.

Another critical practice is the adoption of collaborative planning between different supply chain partners. This approach ensures that all stakeholders share relevant data and insights, leading to improved decision-making regarding inventory placement and replenishment. A study from the Institute for Supply Management highlighted that organizations engaging in collaborative inventory management often experience a 20% improvement in order fulfillment rates. By fostering transparency and communication across the supply chain, businesses can enhance their ability to maintain optimal inventory levels at each echelon, ultimately driving efficiency and customer satisfaction.

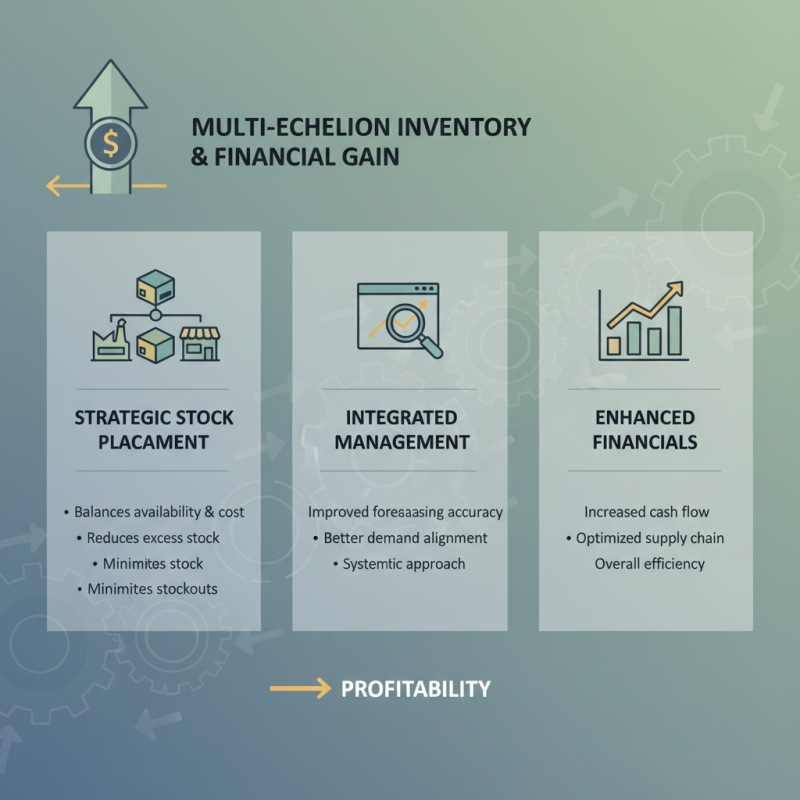

Measuring the Impact of Multi Echelon Inventory on Financial Performance

Measuring the impact of multi-echelon inventory management on financial performance is crucial for businesses aiming to optimize their supply chain operations. Multi-echelon inventory systems strategically position stock across various levels of the supply chain, balancing the need for availability against the costs of holding inventory. By integrating inventory management across multiple tiers, companies can reduce excess stock, minimize stockouts, and improve cash flow. This systematic approach allows for more accurate forecasting and better alignment with demand fluctuations, ultimately enhancing overall financial efficiency.

Furthermore, utilizing multi-echelon inventory not only leads to cost savings but also improves service levels, which can have a direct impact on revenue generation. When inventory is effectively managed throughout the supply chain, companies can respond more quickly to customer needs, ensuring that products are available when and where they are required. This responsiveness can drive customer satisfaction and loyalty, resulting in repeat business and positive word-of-mouth. Consequently, organizations that implement best practices for multi-echelon inventory management can see tangible benefits reflected in their financial performance, including higher profit margins and increased market share.

Related Posts

-

Top 5 Benefits of Multi Echelon Inventory Optimization: Boost Efficiency by 30%

-

10 Best Managed Inventory Tips for Streamlining Your Business Operations

-

Top 10 Tips for Choosing Tk Logistics and Warehousing Solutions

-

Understanding Tk Logistics And Warehousing Services For Your Business Needs

-

2025 How to Optimize Container Transport for Global Shipping Efficiency

-

2025 How to Optimize Intermodal Freight Train Efficiency and Reduce Costs