What is Pallet Transport? Understanding Its Importance and Benefits in Logistics

Pallet Transport plays a pivotal role in the logistics and supply chain industry, serving as a fundamental method for the efficient movement of goods. As businesses continue to globalize and the demand for rapid delivery escalates, understanding the mechanisms and advantages of pallet transport becomes increasingly essential. This mode of transport offers significant benefits, including streamlined operations, enhanced inventory management, and reduced labor costs, making it a preferred choice for many organizations.

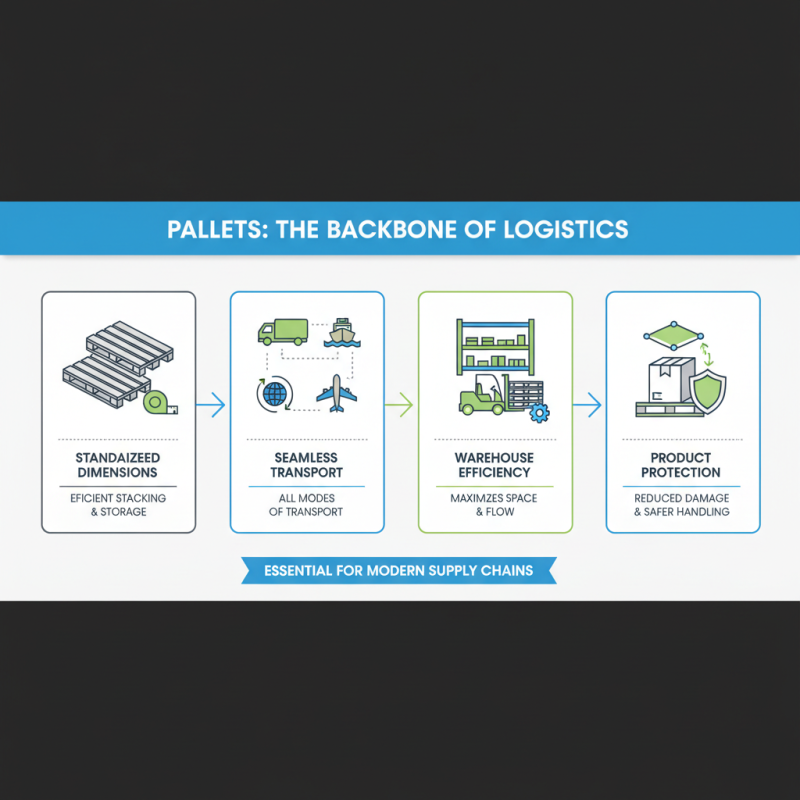

The importance of pallet transport extends beyond mere convenience; it impacts the overall efficiency and effectiveness of supply chains. By utilizing standardized pallets, companies can ensure consistency in handling and storage while maximizing space in warehouses and transportation vehicles. Furthermore, pallet transport facilitates the smooth transfer of goods between different modes of transport, minimizing disruptions and delays. As the logistics landscape evolves, harnessing the capabilities of pallet transport is critical for businesses aiming to optimize their operations and stay competitive in the marketplace.

What is Pallet Transport? A Definition and Overview

Pallet transport refers to the method of using pallets—flat structures that support goods during storage and transportation—to streamline the movement of products within the logistics industry. This practical approach allows for the efficient handling, stacking, and storage of materials, thereby maximizing space and minimizing damage to goods. Pallets are typically made from wood, plastic, or metal and are specifically designed to be lifted by forklifts or pallet jacks, enhancing the speed and safety of loading and unloading processes.

The significance of pallet transport in logistics cannot be overstated. It plays a crucial role in facilitating smooth supply chain operations, as it allows for easier and more organized handling of inventory. By using standardized pallets, businesses can achieve consistency in shipping practices, which simplifies warehousing and distribution. Furthermore, pallet transport reduces labor costs and increases efficiency, making it an essential component in modern logistics management. Overall, understanding the fundamentals of pallet transport is vital for companies aiming to optimize their logistics strategies and improve their overall operational performance.

Pallet Transport Efficiency in Logistics

This bar chart illustrates the efficiency of pallet transport in logistics across different transportation methods. The data shows the average loading capacity and time efficiency associated with each method, highlighting the benefits of using pallets in the supply chain.

The Role of Pallets in the Logistics Industry

Pallets play a vital role in the logistics industry, serving as the foundational platforms for the efficient movement and storage of goods. Their standardized dimensions allow for seamless stacking and storage, making them essential for transporting goods across various modes of transport. In warehouses, pallets facilitate easy handling and organization, helping to maximize space and streamline the flow of inventory. The use of pallets not only improves loading and unloading efficiency but also enhances safety by minimizing the risk of damage to products during transit.

Tips: When selecting pallets for your logistics needs, consider the material and design that best suits your product type. For instance, wooden pallets are sturdy and reliable for heavy loads, while plastic pallets may be beneficial for lighter, sensitive items due to their resistance to moisture and chemicals.

The adoption of pallets also contributes to reducing the carbon footprint of logistics operations. By optimizing space both during transportation and in storage, pallets help to decrease the number of trips required to move goods, thereby saving fuel and lowering emissions. Furthermore, the recycling and repurposing of pallets promote sustainability within the logistics sector, aligning with the growing trend towards environmentally responsible practices.

Tips: Regularly inspect and maintain your pallets to ensure they meet safety standards and longevity. Consider implementing a pallet management system to track usage and inventory, which can lead to significant cost savings in the long run.

Benefits of Using Pallet Transport for Goods Handling

Pallet transport plays a critical role in the logistics industry, significantly enhancing the efficiency and effectiveness of goods handling. One of the most prominent benefits of using pallet transport is its ability to streamline the loading and unloading processes. According to a report by the Logistics Management Association, logistics operations that implement palletization can improve loading efficiency by up to 40%. This not only speeds up the transfer of goods, but also reduces labor costs associated with manual handling.

Additionally, using pallets for transporting goods can significantly minimize product damage during transit. The Material Handling Industry of America (MHIA) finds that pallets can reduce damage rates by around 80% compared to non-palletized shipments. This is primarily because pallets provide stability and protect products from shifting during movement. Furthermore, the consistency of using standardized pallet sizes fosters easier inventory management and enhances supply chain coordination, which is crucial for businesses aiming to optimize their operations and meet customer demands promptly.

Different Types of Pallet Transport Methods

Pallet transport plays a vital role in the logistics industry, with various methods tailored to meet the specific needs of supply chain operations. One of the most common types is road transport, which significantly benefits from the flexibility and efficiency pallets provide. According to the Freight Transportation Services Index, road transport accounted for approximately 70% of total freight tonnage in the U.S. as of recent reports, emphasizing the pivotal role of pallets in optimizing capacity and reducing handling time.

Rail transport is another critical method, particularly for long distances and bulk shipments. Utilizing standardized pallets allows for efficient loading and unloading, minimizing transit times. The Association of American Railroads reported that intermodal freight, which often relies on palletized cargo, has seen a 5% increase in volume year-over-year. Additionally, the use of pallets in sea freight helps streamline operations in ports, where time is of the essence.

The International Maritime Organization's data indicates that approximately 90% of global trade is carried by sea, and with standardized pallet sizes, ships can maximize cargo space effectively, ensuring that logistics operations run smoothly.

Each pallet transport method not only enhances efficiency but also significantly contributes to cost savings and sustainability goals in logistics. These advantages are crucial in an increasingly competitive market, where optimizing supply chains has become essential for success.

Best Practices for Efficient Pallet Transport Management

Efficient pallet transport management is crucial for optimizing logistics operations. To ensure successful pallet management, organizations should focus on three core areas: proper planning, effective tracking, and regular maintenance. Every logistics operation begins with a well-thought-out plan. This involves determining the right types of pallets for specific products, assessing transport routes, and scheduling deliveries to minimize delays. A strategic approach can significantly cut costs and enhance delivery timelines.

Tips: Utilize a pallet management system that incorporates real-time tracking technology. This will allow you to monitor your pallets throughout the entire transport process, ensuring that you have up-to-date information on location and condition, reducing the risk of loss or damage.

Additionally, regular maintenance checks and staff training are essential. Employees must be knowledgeable about proper handling techniques to avoid accidents that could damage pallets and their contents. Investing in employee training enhances safety and efficiency, ultimately leading to a smoother transport process.

Tips: Create a checklist for regular equipment maintenance and train staff to conduct routine inspections. This not only extends the lifespan of your pallets and transport equipment but also minimizes unforeseen disruptions in your logistics operations.

Related Posts

-

How to Optimize Groupage Transport for Cost Effective Shipping Solutions

-

Top 10 Benefits of Multi Echelon Inventory Optimization for Supply Chain Management

-

2025 How to Optimize Intermodal Freight Train Efficiency and Reduce Costs

-

Understanding Multi Echelon Inventory: Key Benefits and Best Practices

-

Top 5 Benefits of Multi Echelon Inventory Optimization: Boost Efficiency by 30%

-

10 Essential Tips for Optimizing Tk Logistics and Warehousing Efficiency